It is said that Torres created the basic structure of today’s classical guitar. It is true that the basic structure is based on that, but new production techniques are being introduced little by little. I’d like to introduce you to these new generation production techniques.

The articles on this site about classical guitar materials and the instrument itself are summarized in the following articles:

Double-top

One of the most major new production techniques is the double top. Matthias Dammann and Gernot Wagner are said to have been the first to develop this production technique.

通常のクラシックギターは薄く削った1枚の木の板からできています。正確には、薄い板を何枚か張り合わせているのですが、縦方向には1枚の板です。このような構造は単板ともいわれ、ベニヤ板(合板)ではないことを表しています。

On the other hand, double top, as the name suggests, is made of two boards laminated together. In this sense, it is not a veneer but a plywood.

Structure with a strong structure sandwiched between thinly shaved wooden boards

It is common to put some kind of structure between the two boards instead of simply laminating them together.

In the photo above, a material called NOMEX from DuPont is sandwiched in between. This material is a strong fiber and is resistant to humidity.

The thinner you cut the wood, the easier it is to vibrate, not just for classical guitars. However, the thinner you make it, the weaker the board becomes.

With a double top, it gets both strength and ease of vibration by putting a strong structure between the thinly shaved boards.

Difficult to build

It seems so easy to shave the board thinly and put something in between. But it is not true.

First, it is difficult to put the structure precisely between two straight boards and stretch them together. If it floats even a little, it will interfere with vibration and cause noise, so it requires an elevated level of skill.

Also, as you can see in the picture above, the structure is not simply placed between two thin boards. It is common to shave off only a part of the board to put the structure in, and the sound varies depending on where and how big it is put in.

For this reason, the sound of a “double top” is not generally the same.

Also, the type of wood, spruce on the top and cedar on the bottom, and the bracing can also change the sound.

It seems to be quite a deep structure like this.

Capable of building loud guitars

The most important advantage of the double top guitar is the volume.

The thinly shaved plate vibrates greatly and can generate a large volume.

On the other hand, some people don’t like the sound of a double top because it sounds different from a traditional guitar. Some people say its projection is not good.

Either way, it’s a technique used by many of today’s top professional guitarists.

Enhanced Wood

This is a new method of sound board developed by the German maker Sebastian Stenzel.

He claims that this solves the problem of the lack of projection of double top guitars.

See the following article for more details:

Raised fingerboard

A raised fingerboard, as the name implies, is a guitar with a raised fingerboard construction.

通常のギターは黒色の指板が表面板と接していますが、レイズドフィンガーボードの場合はネックの一部が表面板にまで延びていて、表面板と指板が離れた構造になっています。

I also use this type of guitar:

It’s not simply the fingerboard lifting

The point of a raised fingerboard is that it doesn’t simply extend the neck and lift the fingerboard.

普通のギターは以下のような構造になっています。指板は本体と接しており、ネックは本体と横で接しているか中に入っており、表面板の上にはありません。

On the other hand, here is a wrong image of a raised fingerboard that is often mistaken:

単純にネックが上に移動し、表面板と接しています。確かに、名前からするとこれでも間違っていないのですが、こうしてしまうと本体とネック、指板の位置が変わり、弾きづらそうです。

The correct raised fingerboard construction looks like this

実は、通常のクラシックギターから変わっているのは表面板の角度です。表面板が斜めに沈み込む構造になっていることで、ネックの一部が露出し、指板が持ち上がります。

The relationship between the back and side panels and the fingerboard is the same as on a regular classical guitar. This means that the positional relationship is the same as when you play a normal classical guitar.

表面板と弦の角度が大きくなることで音量増大

One of the most popular benefits of raised fingerboard construction is that it makes it easier to play in the high position. However, this is actually a secondary effect.

最も大きなポイントは表面板と弦の角度が大きくなるという点です。通常はこれらは平行ですが、上の図にもある通り、レイズドフィンガーボードでは角度がつきます。すると、弦の振動が表面板に伝わりやすくなり、音量が大きくなるようです。特に低音に効果が大きいそうです。

また、他の音量を向上させる技術に比べて音色に与える影響が小さいのもメリットといえます。

There is also a way to make the fretboard and the surface plate not touch each other

In addition, some of them havefloating fingerboards from the sound boards.

When the sound board and fingerboard are glued together, that area does not vibrate. But by floating it, a larger area can be made to vibrate.

Difficult to build, the player misjudges the position

Raised fingerboards are also said to be more difficult to make than normal guitars. The neck, which is usually stored inside the body of the guitar or just in contact with it, has to be exposed, and the side panels have to be slanted, so the degree of difficulty is probably higher than for parallel fingerboards.

また、演奏者にとって、指板が表面板と接していないことからハイポジションがわかりづらくなるというデメリットもあります。特に、12フレットが遠近差でわかりづらいです。

For this reason, only Thomas Humphrey, who is said to have been the first to use the raised fingerboard, and Sakurai in Japan use the raised fingerboard, while the rest use the half-raised finger, which has a relatively small lift.

The structure with a small lift seems to be rather used in recent years.

Lattice bracing

Lattice bracing is also known as waffle bracing.

ブレーシングとは表面板の裏に張り付ける板(力木)の配置のことです。通常のクラシックギターは以下のようなブレーシングとなっています:

This structure is called fan bracing. In this fan bracing, there are various devices such as asymmetry and number of fun bracings by each maker.

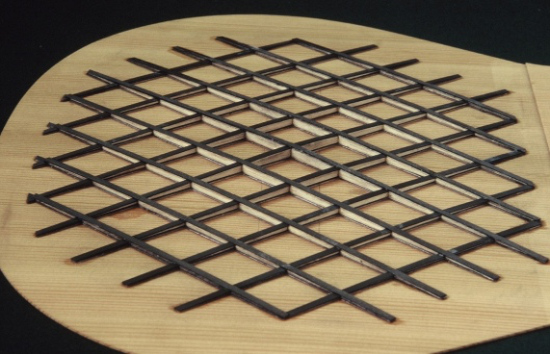

Lattice bracing, on the other hand, has the following bracing arrangement:

It gets its name from the fact that it looks like a gardening divider or a waffle.

It is said to have been first developed by Greg Smallman in Australia.

For your information, there are many other types of bracing.

表面板を薄くして振動しやすくすることが可能

このラティスブレーシングのメリットは表面板を強固にできるという点です。

ブレーシングには表面板を補強するという意味もあるのですが、ラティスブレーシングはこの点に特化しています。これにより、同じ強度であれば表面板を薄くすることができます。表面板が薄くなれば振動しやすくなり、大きな音が出るわけです。

For this reason, not only wood but also carbon fiber is sometimes used as a material for bracing.

Lattice bracing = not a Smallman structure.

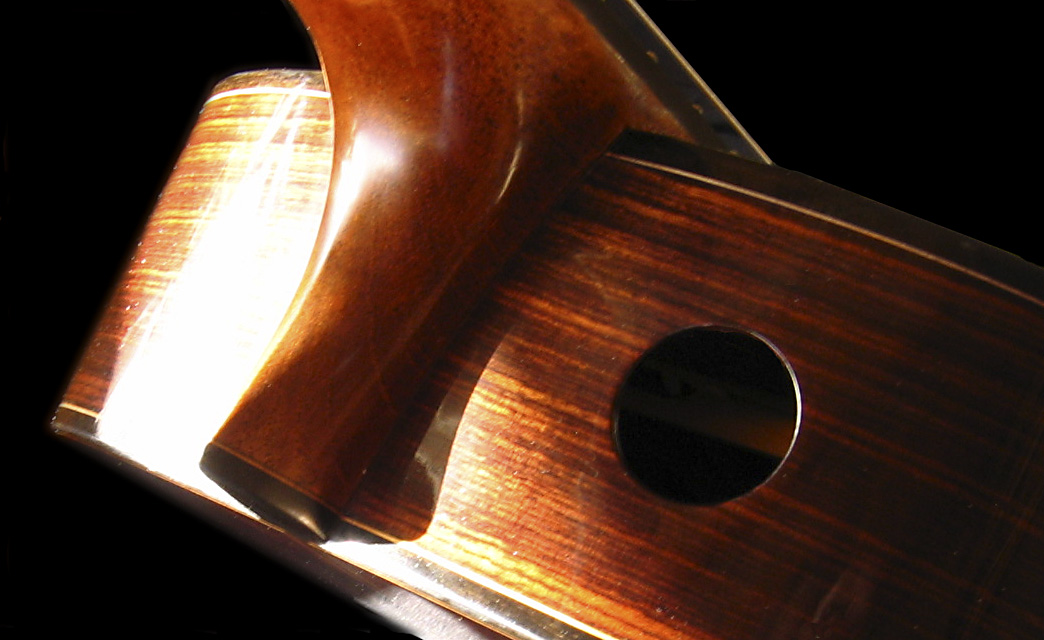

注意したいのはラティスブレーシングがスモールマンの構造を必ずしも表しているというわけではない点です。スモールマンの構造の特徴は以下の写真にある通り、表面板の振動させたい以外のところを振動させないようにしている点にあります:

この写真の中でラティスブレーシングになっている部分が表面板です。あとは薄い表面板を支えたり、余計なところが振動しないようにするための構造になっています。側板および裏板も2重構造にして振動しないようにしています。Aフレームと呼ばれているようです。

By doing this, it is trying todirect all the vibrational energy of the strings to the sound.

We don’t know if they adapt A-frame or if they simply use lattice shaped bracing. As you can see, Smallman construction can be very heavy, so a guitar with non-heavy lattice bracing is not likely to be Smallman construction.

However, guitars with the Smallman construction have a unique tone due to the above characteristics. Some people find the Smallman tone unacceptable.

Sound port

サウンドポートはサウンドホールともいわれ、表面板に開いた1つの穴以外に側板等に穴が開いた構造を指します。

For example:.

The position, shape, and number of holes are various, and some of them can be covered with a lid.

Can hear the sound players made.

通常のクラシックギターでは音は表面板の穴から出ます。音は指向性を持っているのでこの穴から前方に主に出るため、演奏者は自分が出した音を観客と同じように聴くことはできません。

However, with a sound port aimed at the player, the sound can be as close to what the audience is hearing as possible.

ギターの音は一般的には観客が聴いた際にベストになるように作られていますので、サウンドポートにより自分が弾いていても楽しいギターとすることが可能です。

What about all the talk of better treble sound and volume?

サウンドポートを設けることで、高音がこもらずに抜けがよくなるという話もあります。すべての音域が1つの穴から出ることがベストではないでしょうから、これはあるかもしれません。

On the other hand, from Smallman’s theory, it would be concerned about the effect on volume if there are holes in extra places. I haven’t heard of anything extremely small, and many luthiers have sound ports, so you may not have to worry about it as much.

Acoustic tube

ラファウ・トゥルコウィアック(Rafal Turkowiak)というポーランドの製作家が採用している、ネックに穴を開けることで音を改善しようとする試みがアコースティックチューブです。

This improves the sound transmission by 20%.

Probably not just a hole in the neck, but also a hole in the sound board to allow sound to pass through.

By the way, they have a patent on it.

Arch back

A classical guitar usually has a straight back plate. This is made by cutting the wood into thin strips, but the archback is made by cutting a thick piece of wood into a curved surface. This is the same production method used for violins.

The advantage is that the sound reflected from the back plate is concentrated in the sound hole, like a parabolic antenna, which is said to increase the volume.

The disadvantage is that the curved surface increases the area, so the guitar becomes heavier.

(P.S.): I received an opinion from a reader that it is common for acoustic guitars to simply have the board lightly bent into an arch shape, which is called an arch back.

Trans-acoustic guitar

通常のクラシックギターは弦の振動をそのまま表面板に伝えて音を出します。

これに対し、ヤマハのトランスアコースティックギターといわれる製品は、弦の振動を一度ピックアップで拾い、それを電気信号にしてアクチュエーターに伝えて表面板を振動させることで音を出します。

The following article was previously published:

電気信号に変えてアクチュエーターで表面板を振動させるので、音量を自由に調整することが可能です。通常のクラシックギターでは出せないような大きな音も自由自在です。また、エコーなどのエフェクトもかけることが可能となります。

P.S. It seems that only the line out can adjust the volume…

通常のエレアコやエレキのようにスピーカーから音を出すのではなく、あくまで表面板が振動した音なので、音色が通常のクラシックギターに近いというのもメリットです。

まだこの製品は出たばかりですが、将来的には歴史的な名器(トーレス、フレタ、ハウザーとか)の振動を再現して、音色や音量も近いものを出せたりしないですかね。

I hope this article helps you choose from a vast array of options.

The big difference with smartphones and computers is that the latest technology isn’t always the best.

Everyone has different tastes, some people like 19th century guitars, others like the sound of a double top.

However, when you are thinking about which guitar to buy from a huge selection of guitars, this kind of knowledge will make your choice easier.

I hope that new techniques will still emerge and the classical guitar will continue to develop.